Unfortunately for consumers buying prepackaged, sweetened foods or those eating out, it is difficult to know the source of the white refined sugar that these foods contain.

Consumers should be forewarned that making a company inquiry will not usually resolve their concerns because many manufacturers purchase both sugar produced from sugar beets and sugar produced from sugar cane. Robinson stated, "Common practice at many manufacturers is to store refined sugar from both sources in the same bin, thereby co-mingling the two." It is likely that a certain prepackaged or restaurant-served food may contain both cane and beet sugar. Proportions of each in any given serving probably vary over time.

The Exact Role of Bone Char In Sugar Refining

A bone char filter acts like a crude filter and is most often used first in cane sugar refining. To sugar scientists, it is a 'fixed bed adsorption' filter, meaning that particles unlike itself stick to it. It is also the most efficient filter for removing colorants; the most frequently found colorants are amino acids, carboxylic acids, phenols, and ash.

The bone char is not as good at removing impurities such as inorganic ions, so after being put through bone char, sugar may be passed through activated char-coal or an ion exchange system as well. The sugar also goes through several different filters to remove larger particles. Nevertheless, bone char filters are the most efficient and most economical whitening filters, thereby maintaining their position as the industry’s cane sugar filter of choice.

Connie Hunter, Consumer Relations Specialist for Domino Sugar and the C&H Sugar Company, said the bones used to make bone char come from "non-European cattle." Robinson told us that American Sugar Refining purchases its bone char from a Scottish company, which did not respond to our inquiries. He said that he has been told these bones come from cattle that have died naturally in Brazil, India, Morocco, Nigeria, and Pakistan. The bones are sun-dried and incinerated for 12 hours at more than 700 degrees Celsius. During the burning process, all organic matter that may be present—including viruses, bacteria, and proteins—is destroyed, leaving only an inert granular substance that is 10 percent elemental carbon and 90 percent calcium hydroxyapatite.

The other major company that sells bone char to the sugar industry is the American Charcoal Company, which was started in 2002 and is located in Wyoming. According to American Charcoal representative Craig Giles, the company gets its bone char in ready-to-sell form from Brazil’s cattle industry. Imperial/Savannah Foods purchases its bone char from both the Scottish company and American Charcoal.

How Much Bone Char Is Used?

Paul Caulkins, the Corporate Quality Assurance Manager of Imperial/Savannah Foods, said that little bone char can be obtained from a single cow "since only the dense bones of the animal, such as the pelvic bones, can be used." After checking with his suppliers, Caulkins informed that "one cow averages 82 pounds of total bone. About one-fourth to one-fifth of the total weight (between 17 and 20 pounds per animal) is the load-bearing bone used for char (due to its strength). Since our yield conversion to char from that is approximately 50 percent, on average, one cow will produce nine pounds of bone char."

Sugar companies purchase large quantities of bone char for several reasons, the first being the sheer size of their operations. Large commercial filter columns often measure 10 to 40 feet high and five to 20 feet wide. Each column, which can filter 30 gallons of sugar per minute for 120 hours at a time, may hold 70,000 pounds of char. If nine pounds of char is produced by one cow and 70,000 pounds are needed to fill a column, a simple math calculation reveals that the bones of almost 7,800 cattle are needed to produce the bone char for one commercial sugar filter. (We did not receive a verification of this estimate from another source.) Furthermore, each refining plant may have several large filter columns.

Companies use up their supplies of bone char relatively quickly. Since bone char is the first filter used in the sugar refining process, its granules absorb large amounts of colorants and impurities. This means that the overall working life for bone char granules may be reduced significantly. In general, bone char may last for five to 10 years, depending on the volume of raw material filtered through it and the level of impurities in the sugar. The bone char may be rejuvenated several times by burning it at 9,500 degrees in a kiln for 20 minutes, but this typically occurs only once.

Over time, some of the char disintegrates and becomes too small in particle size to filter anymore, so that portion is screened off. Also, colorants and other impurities begin to permanently fill the bone char's microscopic holes, compromising its effectiveness. These impurities make the char heavy, and it can't be volatilized off when rejuvenated in a kiln. Even with the massive quantities of bone char that industries secure, these factors contribute to the need to replenish their bone char stores regularly.

At this time, the cane sugar industry believes that only more cow bone char can fill the same roles as well as bone char. Other technologies, such as reverse osmosis, have been under study for a long time, but they don’t perform as well as bone char does at the high temperatures used in the refining process. Perhaps by the time of our next update on the sugar industry, bone char will no longer be a mainstay of sugar refining, especially since Caulkins stated that the prices of bone char, activated carbon, and ion exchange technologies are comparable. What’s needed is improved technology, consumer pressure on the industry to change its refining methods, and the capital investment—a tall order for now but maybe a reality one day.

Organic Sugar: Always Bone Char-Free

The increasing popularity of organic foods in the United States has bolstered the production of the organic sugar industry. In fact, The VRG is happy to report that there is a large market niche for organic sweeteners.

To maintain its organic integrity, organic sugar is only minimally processed or not refined at all. Since bone char is not on the National Organic Program's National List of Allowed and Prohibited Substances, certified USDA organic sugar cannot be filtered through bone char. In fact, the technical directors of both Imperial Sugar and American Sugar Refining told that organic sugars are only milled and never go to the refinery where the bone char filters are located.

A common processing aid, lime, is used as a clarifying agent in organic cane sugar processing, removing cane fibers and field debris. Since lime is on the National List, it can be used in organic sugar production. However, because the lime itself is synthetic, no organic sugar processed in this manner can ever be certified 100% USDA Organic; the maximum certification it can receive is 95% certified organic. Consequently, any sugar-containing product made with organic sugar can achieve only a 95% certified organic rating.

There are a few organic clarifying agents, such as the seeds of the drumstick tree (Moringa oleifera) and the edible fruit of Cordia myxa, that could produce 100% certified organic sugar. However, Dr. Stephen Clarke, Director of Technical Services at Florida Crystals, said, "These aids are a substitute for the polyacrylamide materials that we conventionally use in clarification and not for the lime that is used for pH adjustment. The 'natural’ flocculants are basically acidic polysaccharides extracted from succulent plants similar to aloe." Clarke informed The VRG that Florida Crystals tested some organic clarifying agents approximately two years ago, but their performance was “poor and inconsistent." He did say, "Although the potential is there, the real problem is that another crop has to be grown and processed."

Another reason why bone char is not used in organic sugar production is that its decolorizing function is neither needed nor desired. U.S. organic laws do not have any strict standards regarding the color of organic sugar (like those that exist for conventional white sugar). Unrefined sugar is naturally light tan to brown, and the medium to darker colored sugars are often described as 'golden.' "Retail customers seem to prefer this color and associate it with a more natural, less processed product," stated Tom Hasenstaub, the Organic Program Manager at Florida Crystals. He added that the natural color of organic sugar "has been somewhat problematic to certain industrial customers who are trying to formulate organic processed products to emulate the color profiles of their conventional products."

At the present time, most organic sugar used in the United States is imported from Paraguay, Brazil, and Mexico. Florida Crystals is the only U.S. producer of organic sugar, with approximately 4,000 acres of rotating organic sugar cane and rice in production and an additional 900 acres planned for the upcoming growing season. However, this quantity meets only 20 percent of U.S. demand. Approximately 80 percent of all organic sugar produced in the U.S. is used in industries manufacturing sugar-containing products, while 20 percent is purchased directly by consumers.

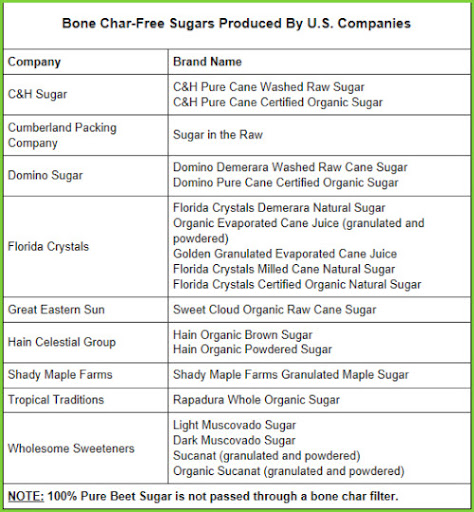

Below is the table list brands of organic sweeteners that determined to be bone char-free, based on correspondence with the manufacturers.

Today in the United States, all organic sugar is produced from sugar cane. According to Ruthann Geib, the Vice President of the Sugar Beet Growers Association, there is no organic sugar beet production in the United States at this time. Clarke noted, "There are no technical reasons preventing the production of organic beet sugar; it has been done in Europe."

Watch Out For Bone Char: Tips For Consumers

On your next trip to the sugar aisle at the grocery, you may notice many bags of sugar that are labeled "100% Pure Cane Sugar." Most likely, this sugar was refined using bone char. In contrast, sugar in bags labeled "100% Pure Beet Sugar" was never passed through a bone char filter.

Questions soon arise about sugar labeled, for instance, "Granulated Sugar." There is no way to tell based on this phrase alone whether the sugar had been filtered through bone char. The phrase "100% Sugar" is equally ambiguous. Supermarket chains that purchase sugar from a large sugar company but label it as their own may not indicate which type of sugar it is.

Brown sugar is made by adding molasses to refined white sugar. Therefore, companies that use bone char to produce their white sugar will also use it to produce their brown sugar. The same is true for confectioner’s sugar, which is refined white sugar with added corn-starch. Invert sugar is filtered through the use of bone char. Fructose may but does not typically involve a bone-char filter. Molasses, turbinado, demerara, and muscovado sugars are never filtered through bone char. Evaporated cane juice is also bone-char free. If in doubt about any product, concerned consumers should direct inquiries to the manufacturer.

Tip Natural Sugar

By : Jeanne Yacoubou, MS

Vegetariam Resource Group

Tip Natural Sugar

If you love corn on the cob as much as I do, here’s a tip to make it even more delicious. When boiling corn on the cob, if we add just a pinch of natural sugar, it will help bring out the corn’s very own sweetness.

By : Jeanne Yacoubou, MS

Vegetariam Resource Group

Choose Organic Sugar Product Because :

· Healthier alternative : by choosing organic sugar, you can avoid exposure to chemicals introduced in the growth or manufacturing stages of conventional sugar. Additionally, organic sugar retains traces of the vitamins and minerals present in the plant. Its contains : Vitamin B2- is essential for a healthy nervous system, Iron - essential for red blood cell formation, Calcium - is vital for healthy bone growth, Phosphorus - for healthy bone and teeth development, Potassium - works with other minerals like calcium to strengthen muscles and prevent cramps, Magnesium - is a mineral that helps improve calcium absorption. Notice : use in moderate way because is still sugar.

· Enviroment Friendly : Farmers do not use pesticides, herbicides, or synthetic fertilizers on sugar cane or sugar beets grown for use in manufacturing organic sugar.

· Animal Welfare : Some sugar refineries use charcoal made from animal bones as a filter to remove color and impurities. Organic sugar manufacturers do not use animal bone char for filtration.

Buy Organic Sugar from Amazon.com

Wholesome Sweeteners Fair Trade Organic Sugar, 16-Ounce Pouches (Pack of 12)

A blond, delicious, natural Organic Sugar perfect for sprinkling, baking and hot and cold drinks. Made from freshly squeezed Organic Cane Juice, which is evaporated and crystallized on the same day it is harvested. Use as a 1-for-1 organic replacement for refined sugar. The Fair Trade label guarantees the consumer a fair price is paid directly to the farmer for the sugar cane they grow. Returning real value to the primary agricultural producers means they can compete with factory farms whilst protecting sustainable farming practices. It also means they can enjoy higher living standards and develop thriving communities. A spoonful of Fair Trade Sugar really does make the world a sweeter place! Fair Trade, organic and kosher certified. Suitable for vegan, vegetarian, Halal and plant-based diets. Product of Paraguay.

Hain Pure Foods Organic Sugar, 24-Ounce Units (Pack of 6)

All purpose natural sweetener. USDA organic. Hain Organic Sugar is organically grown. It's produced with earth-friendly processes using renewable energy sources and rotating crops to protect the environment. Freshly-cut sugarcane is milled, crushed, purified and crystallized in one simple process. It contains no artificial additives or preservatives and is certifies kosher. We're sure you'll love this wonderful natural sweetener. Certified organic by Oregon Tilth. Enjoy!

Wholesome Sweeteners Organic Turbinado Raw Cane Sugar, 24-Ounce Pouches (Pack of 12)

Turbinado's golden crunchy crystals, produced from 100% organically grown sugar cane, are perfect for gourmet coffee, tea, beverages and as a crunchy topping. Made by crushing the freshly-cut cane to squeeze out excess juice, Turbinado is rich in molasses, vitamins and minerals. Cane juice is simply thickened through the evaporation of excess moisture to form a heavy syrup. The syrup is crystallized in a centrifuge, or turbine, to produce the large sparkling golden crystals--hence the name, Turbinado. It is the ultimate topping for cakes, cookies, muffins, crumbles and pies and a wonderful start to the day sprinkled on cereal or fruit. Use as a 1-for-1 replacement for refined white sugar. Organic and kosher certified. Suitable for vegan, vegetarian, halal and plant-based diets. Turbinado is not colored or blended and no animal byproducts are used in its production.

One of the most recent additions to the Domino family carries on a 100-year tradition of making quality sugar - the natural way. Domino Organic Sugar is harvested and milled on the same day from certified organic sugar cane.

No comments:

Post a Comment